Industry 4.0 is a term from practice and stands for a project of the German federal government. In science, the influence of technology on classic production and the networking of people and machines is roughly examined, including the integration of technologies such as Sensors Technologies, 3D printing and Artificial Intelligence (AI).

In the course of my research, I examined two current studies on Industry 4.0 and would like to summarize and compare them below.

Study 1: Bitkom

In the first selected study, Bitkom (2019) surveyed over 550 industrial companies of various sizes on the subject of Industry 4.0. Over half of the companies surveyed stated that Industry 4.0 was being used for the first time. 21% of the companies surveyed are also planning to expand this. A special field of application is the linking of machines with the Internet in order to enable a link and a targeted data analysis.

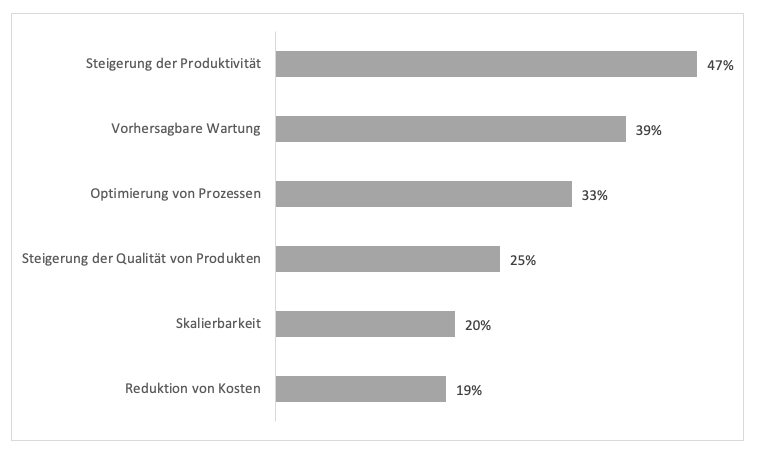

The majority of the companies surveyed state that 20-50% of the machines in production are currently connected to the Internet. According to the companies surveyed, the currently noticeable advantages are primarily the increase in productivity, the predictability of maintenance and the optimization of processes in production. Overall, the benefits currently seem to be minor. The illustration shows other advantages.

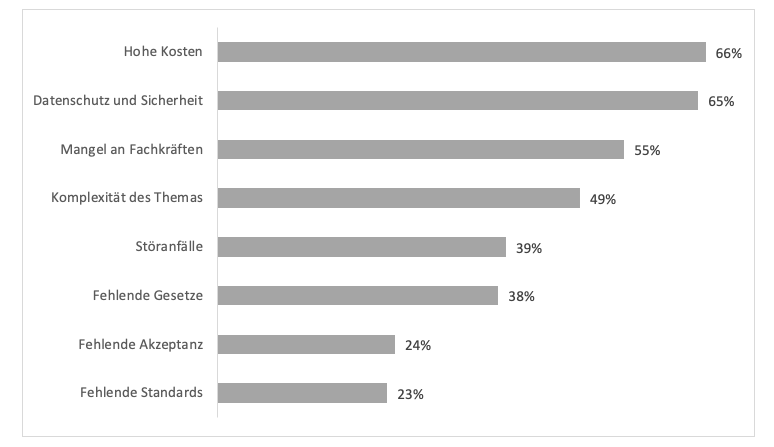

According to the study, the current implementation of Industry 4.0 requires further investments and the hiring of skilled workers. Most companies currently invest around 5% of their sales in technologies that are associated with Industry 4.0. In addition, 50% of the companies each believe that new IT and production specialists will have to be found because of these projects. According to the study, more than two thirds of the skilled workers sought have an academic background and could displace skilled workers with a training background. In addition to the numerous opportunities shown in the following figure, there are also risks that companies currently see as obstacles to projects in the context of Industry 4.0. Above all, there are high investment costs, aspects of data protection and security as well as the lack of skilled workers. Further results are shown in the following figure.

Study 2: Saarbrücken Competence Center

The second selected study was carried out in 2017 by the Saarbrücken Competence Center. With the help of almost 340 interviews with IT managers from production companies, aspects related to Industry 4.0 were examined. The main results of the study are that almost 80% of the participants are currently carrying out projects related to Industry 4.0. Especially with individual measures, the participants noticed the first successes after three months (small efficiency gains). In the case of larger projects, over two thirds of the participants assume that the first potential, specifically increases in sales and competitive advantages, will only become apparent after three years.

But how does this study differ from Bitkom? the difference is found in the potentials. These are as follows:

- Competitive advantage (44%),

- Saving of costs (40.7%) and

- Speed of processes (38%).

Furthermore, possible obstacles to Industry 4.0 were examined in the study, whereby the information also differs slightly from the first study. For example, the shortage of skilled workers does not play a role here. According to the study, the main obstacles are:

- Hacker attacks (47%),

- Industrial espionage (29.7%),

- Production losses (29.5%) and

- Legal problems (26.3%).

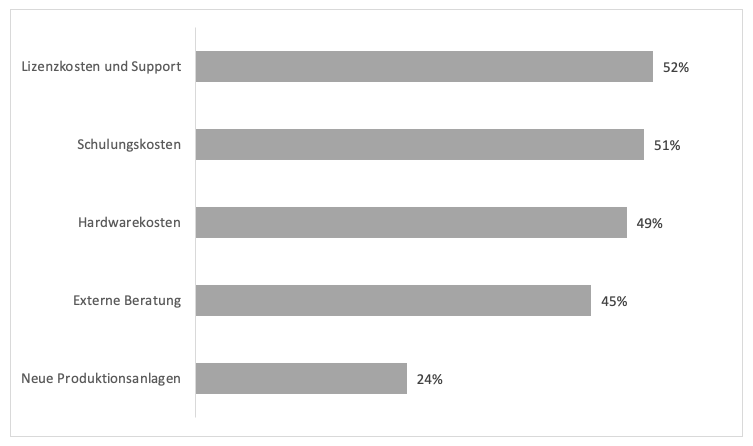

The central point in both studies is almost always the high costs of Industry 4.0 projects. The highest costs are license, training and hardware costs.

Conclusion

Industry 4.0 is used more and more in Germany and is also to be expanded slowly. However, there are obstacles that prevent companies from increasing projects significantly. According to the companies, the high costs in particular are a high risk.

swell

Bitkom. (2019). Industry 4.0 study. Retrieved May 19, 2020, from https://www.bitkom.org/sites/default/files/2019-04/bitkom-pressekonferenz_industrie_4.0_01_04_2019_prasentation_0.pdf

Competence Center Saarbrücken. (2017). IDG study Industry 4.0. Retrieved May 20, 2020, from https://kompetenzzentrum-saarbruecken.digital/wp-content/uploads/2018/10/IDG-Studie2017-Industrie4.0.pdf

Image-Source: Fotolia.de 2016 – buyed License [werbung] [fotolia]