Digitization can now be found everywhere and is spreading like wildfire.

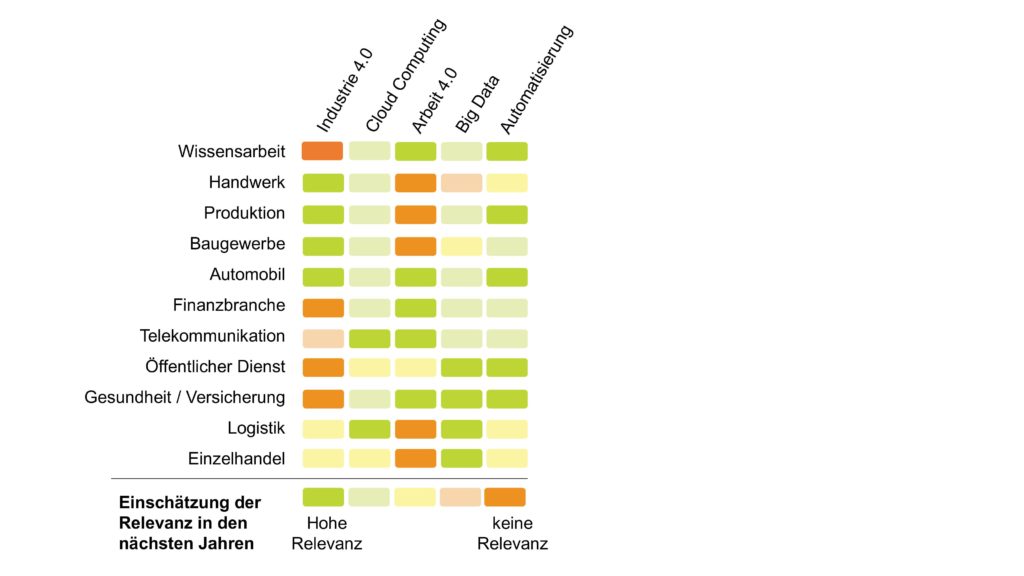

I am therefore now writing a whole series of articles on the subject of digitization. My motivation behind this is that digitization means something different for every industry and type of company and I want to work out these differences. An illustration of the differences in different industries can be found in the following figure.

In this section I would like to go into the actual core of this article and illustrate digitization in the craft.

Industry characteristics

The branch of the handicraft combines human ability with creativity and the handling of materials. The conception of innovation paired with added value and the interdisciplinary linking of ideas and solutions are still the main components of the industry. The craft actually describes by nature that it is linked to flexibility and dynamism. Nevertheless, agile methods and digital support are only slowly finding their way, while the industry is still developing in the direction of Industry 4.0. Traditional companies in particular, as they are often represented in the trades, still like to rely on tried and tested methods, among other things because work 4.0 is comparatively less relevant here.

The current digitization in the craft

However, this does not mean that the craft is completely closed to technology and the introduction of agility. Almost every craft company already has at least one website of its own. Many companies also rely on the use of software solutions to monitor and control their processes, some even on the use of tracking systems for machines and materials or digital innovations such as 3D printers.

Advantages of digitization in the craft

The industry hopes to save time and money through the use of technological aids, agile methods and the digitization of entire work areas. In the future, whole drafts will be planned online. In future, it will be possible to forward the delivery of materials to suppliers detour and in real time. The storage of materials is also planned more cost-effectively as a result. Safety stocks can be recorded in good time and only stored after they have actually been used. In addition, the deployment of employees can be designed as a flexible work organization by planning the distribution across construction sites and customers. In addition, the workforce can be divided more efficiently according to effort and working hours.

Tip:

If you are as excited about this topic as I am, then you can find the entire article series here !