Logistics “includes all tasks for the integrated planning, coordination, implementation and control of the flow of goods as well as the goods-related information from the generation sinks to the consumption sinks” ( Gabler Business Lexicon ). Furthermore, the task of logistics is to provide the right goods at the right time in the right amount in the right place.

Logistics is characterized by a high level of dynamism. Often the definition of which goods actually have to be available at which location and at what time cannot be clarified. So it seems that changeability should be a fundamental element of logistics. For this reason, there has recently been a rethink towards agile logistics.

Agile logistics or is it lean?

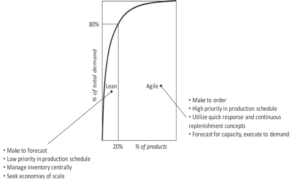

While “Lean” was the absolute keyword in logistics a while ago and every manager proudly showed his Six Sigma Belt, there is now a rethinking towards agile logistics (Valerod 2013, p. 12). According to modern studies, Lean works very well with predictable value chains. However, as soon as there is flexibility and a high level of uncertainty in the supply chain, agile principles are recommended. With agile methods, software developers can already react much faster to changes. True to the credo: Take change for granted and react to it!

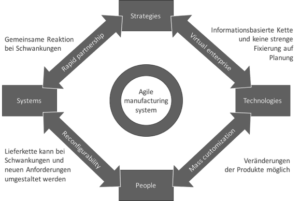

But what exactly is such agile logistics? Kumar et al. (2011, p. 6410) provide a manifest that should describe them. It shows the relationship between people, systems, strategies and technology. This model provides an initial approach for agile logistics and will be examined in detail in the further course of the project. The successful use of Scrum and Co. promotes communication in the supply chain and places greater demands on transparency for the client. This requires a certain amount of trust and shared values.

Agile supply chain

Let us put ourselves in the mind of a major construction site: There are many different players here (suppliers, freight forwarders, site managers, specialist planners, technicians, etc.). All processes are not precisely planned, but as a service provider we have the task of getting all the goods at the right time and reacting immediately to spontaneous changes to the construction. The requirements are sent to us by various site managers and are often not 100% compatible with one another.

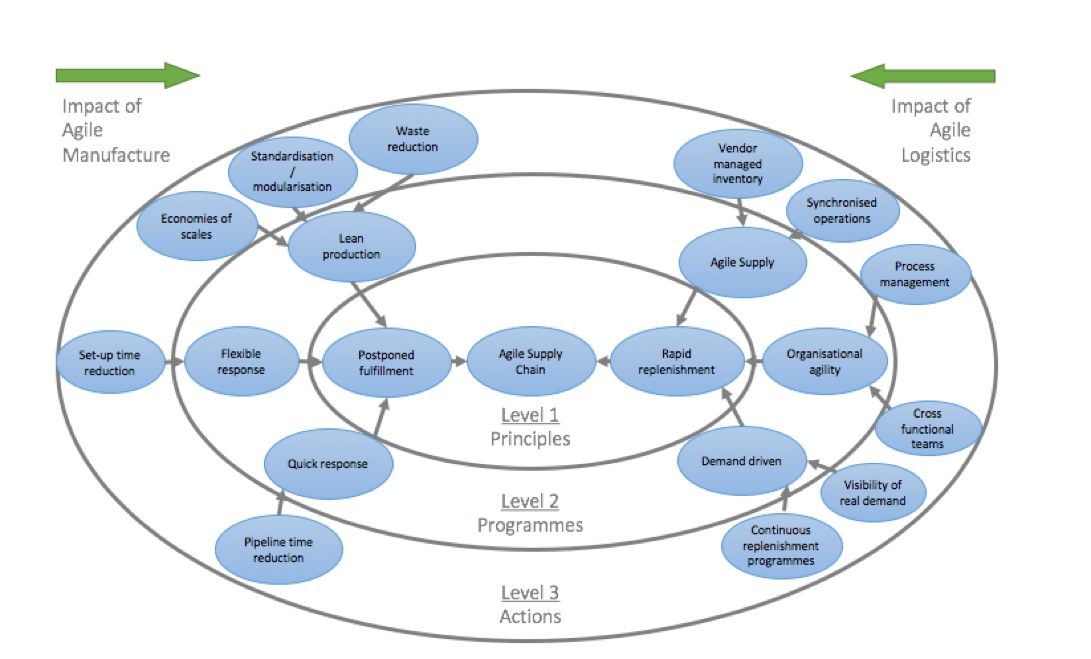

One solution seems to be the principles of the agile supply chain in the figure above. However, the question arises as to how I actually implement this in my logistics. One answer to this could be the new possibilities of Logistics 4.0.

Logistics 4.0 and the agile supply chain?

Logistics 4.0 first and foremost denotes a process revolution in industry. Highly flexible and active units coordinate with one another according to the principle of self-organization. According to the illustration by Kaufmann (2013, p. 26), this small model already shows a clear added value for logistics. This is how logistics become through the comprehensive Industry 4.0 offer much more complex new opportunities with new business models and technologies.

If we summarize the approach of agile logistics and the possibilities, the individual members of the supply chain now have to work more closely and better together. So a common reaction is important. The first interviews showed that Kotler et al. (2010) are absolutely right with their framework. Common values (agility) and goals are now often higher than the price, and for effective cooperation, common values and goals are more important than drafting a contract.

Sales strategy for agile logistics

On the DVZ magazine A survey was carried out and it showed that the logistics managers surveyed expect greater dynamism. 75% of those surveyed expect that the digital transformation can bring greater agility and 70% are already starting to design the digital supply chain, 48% also admit that there is currently insufficient technological support.

4 key technologies were defined for the solution. In the first place there are supply chain ERP solutions, which lead to an improvement of the data collection and follow to the better use of big data solutions. This could use simulation tools that increase predictability. Cloud solutions are also mentioned.

[werbung] Verwendete Quellen anzeigenKaufmann, T. (2015). Business models in Industry 4.0 and the Internet of Things: The path from claims to reality . Berlin: Springer Vieweg.

Kumar, V., Mishra, N., Chan, FTS, & Verma, A. (2011). Managing Warehousing in an Agile Supply Chain Environment: an F-AIS Algorithm Based Approach. International Journal of Production Research , 49 (21), 6407-6426. http://doi.org/10.1080/00207543.2010.528057

Kotler, P., Kartajaya, H., & Setiawan, I. (2010). Marketing 3.0: The new dimension of marketing: From customer to person . Frankfurt am Main: Campus Verlag.

Valerod (2013). Chapter 7 The agile supply chain content . Retrieved from http://de.slideshare.net/valerod2/7-agile-supply-chain-23750309