Digitization can now be found everywhere and is spreading like wildfire.

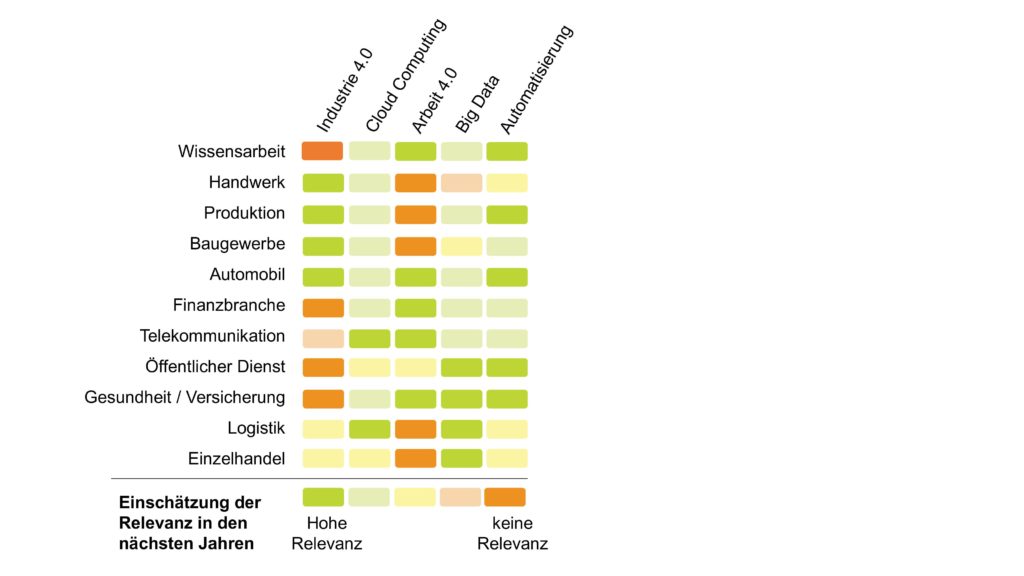

I am therefore now writing a whole series of articles on the subject of digitization. My motivation behind this is that digitization means something different for every industry and type of company and I want to work out these differences. An illustration of the differences in different industries can be found in the following figure.

In this section I would like to go into the actual core of this article and illustrate digitization in production.

Industry characteristics

So far, production in the IT sector has mainly benefited from the pure administration of production-related information or the job of processing orders. Due to the lack of technology and the low use of agile methods, complex relationships between processes and production were difficult to decipher and poorly optimized. Many manufacturing companies have already recognized this problem. They have found help in digitization, as they are increasingly developing in the direction of automated processes and Industry 4.0.

The current digitization in production

The slow arrival of digitization and agility in the production industry is due in particular to the complexity of many systems. Changes and new product introductions have different quick and unequal consequences for a certain sector, especially in production. For example, machines and systems are subject to different life expectancies or databases. While data and information can be accessed much faster and easier in the field of customer-based technologies, this is often associated with much greater effort for manufacturing companies. This higher development effort also requires higher investments. Because of this, this means that you can only draw from a smaller pool of innovations.

In spite of this, technologies such as clouds, for the clear presentation of processes, for example, or modular software platforms for developing several applications at the same time have been used in production. But agile methods for saving costs and implementing a decentralized way of working are also increasingly popular with manufacturing companies.

Advantages of digitization in production

The increasing digitization in this industry promises one thing above all: increased production. Technological developments such as the digital twin exert a strong influence on processes and systems and thus offer a higher degree of control, as software solutions enable, for example, the uniform monitoring of entire production lines. In this way, the functionality of systems and machines can always be monitored and controlled in real time. This ultimately results in the advantage that machine downtimes can be reduced, the reliability of on-time delivery increased and the productivity of production improved. Employees of manufacturing companies can use these new coordination options to link individual systems of production series more efficiently and profitably.

Tip:

If you are as excited about this topic as I am, then you can find the entire article series here !