The term Industry 4.0 is on everyone’s lips. So shows one Telekom survey that among more than 500 executives almost 70% know and follow the term. 22% (of the 70%) thought they were following it intensively and 35% on the edge.

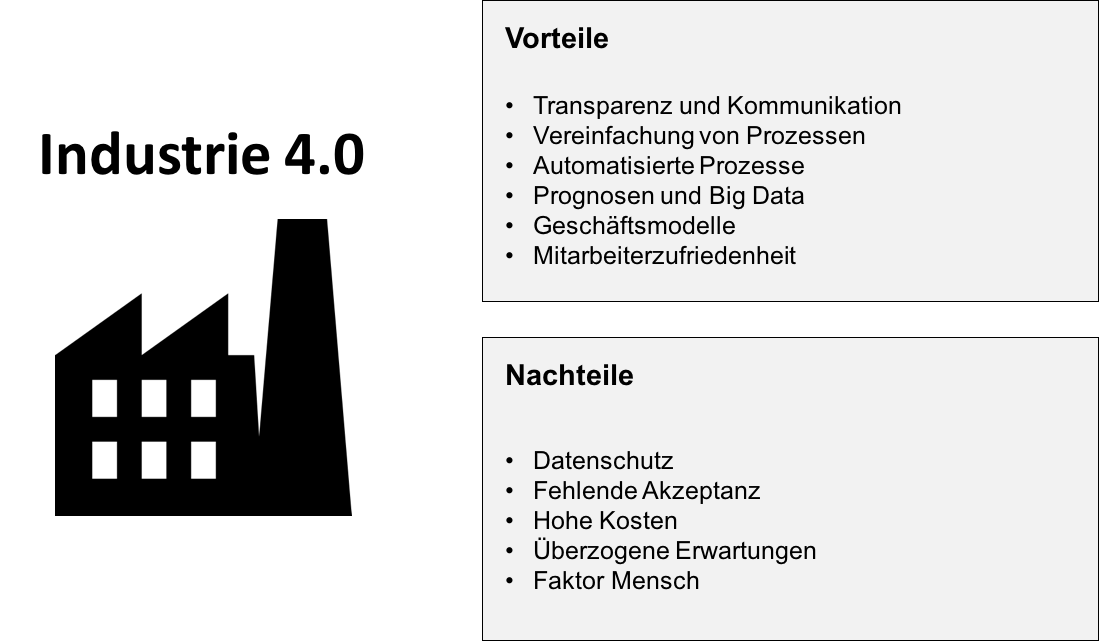

However, if you look at the current situation in medium-sized companies, it shows Study by the Nuremberg Chamber of Industry and Commerce that German companies are following Industry 4.0 but are still waiting and waiting for it to be implemented. More than 70% of the 350 SMEs surveyed describe themselves as waiting or stated that they have not yet implemented any Industry 4.0 scenarios. Only 13% stated that they are currently starting their first attempts and 16.5% that they see themselves as pioneers. So it seems that the disadvantages of Industry 4.0 are deterring entrepreneurs. In addition to the many positive ones, there are of course also disadvantages of Industry 4.0, which will be discussed in this article.

Reading tip: What is Industry 4.0

data protection

It is of course clear to us that data protection is probably the biggest issue in Industry 4.0. In many studies, it clearly cites the disadvantages of Industry 4.0. Since networked machines produce a large amount of data and this is to be sent across the world, it must logically be adequately protected.

On the one hand, there is the risk of misuse of this data and, on the other hand, the encryption and protection of this data could incur high and hardly calculable costs for a company. The question: is it safe now? never actually be answered.

Lack of acceptance

You know: What use is the best tool if nobody is using it? On the one hand, customers should be mentioned here who do not want to use the great tools and dashboards and, on the other hand, also suppliers who do not offer suitable interfaces and the expensive infrastructure becomes useless, so to speak. This can be a danger that every manager should be aware of. An acceptance test should therefore be carried out urgently.

High costs

And what does that cost me now? Service providers for Industry 4.0 will often hardly be able to answer this question. In addition to the tool costs, you can expect consulting and implementation costs, which are hardly calculable. If you look at the studies, these are currently the biggest obstacles in Industry 4.0 for SMEs.

Rushed implementation and expectations

Another point is a hasty implementation. In addition to the human factor, production processes also have to be fundamentally changed and any processes with suppliers and possibly even with customers have to be changed. These are important points in Industry 4.0. However, this point seems to be given less weight, since medium-sized companies are already opposing Industry 4.0 with great wait and see.

However, I think that it certainly takes a lot of planning to really implement Industry 4.0 and not just introduce a tool quickly. The expectations shouldn’t be too high either. It won’t solve all problems. This point is arguably the more significant in the wait-and-see attitude or disappointment of some entrepreneurs.

Human factor

What would a factory be without people? Probably quite lonely and highly automated. Since the factory without people is currently still a vision of the future, managers have to pick up their employees and train them in the new possibilities and tools.

On the other hand, IT-savvy employees are also needed, who will be difficult to find in view of the shortage of skilled workers. Often these have to be poached and are accordingly expensive. You can find out how you can still get some skilled workers in my article on skills shortages.

Reading tip: Shortage of skilled workers in medium-sized businesses!

Conclusion: Disadvantages of Industry 4.0

Industry 4.0 is on everyone’s lips and presents numerous risks. So it is logical why the German middle class is still waiting. In addition to data protection, high costs, exaggerated expectations, a lack of acceptance and the human factor, as always, not everything is only associated with risks.

Reading tip: Book tips on Industry 4.0

So there are not only disadvantages of Industry 4.0, but there are also numerous opportunities in Industry 4.0, which you should weight with the risks. Therefore, read the next to them as well Advantages of Industry 4.0.